Collector Mounting

Apricus ETC solar collectors can be mounted on a roof, wall, the ground or custom built structure like shown below on the roof of a restaurant.

Design Advantages

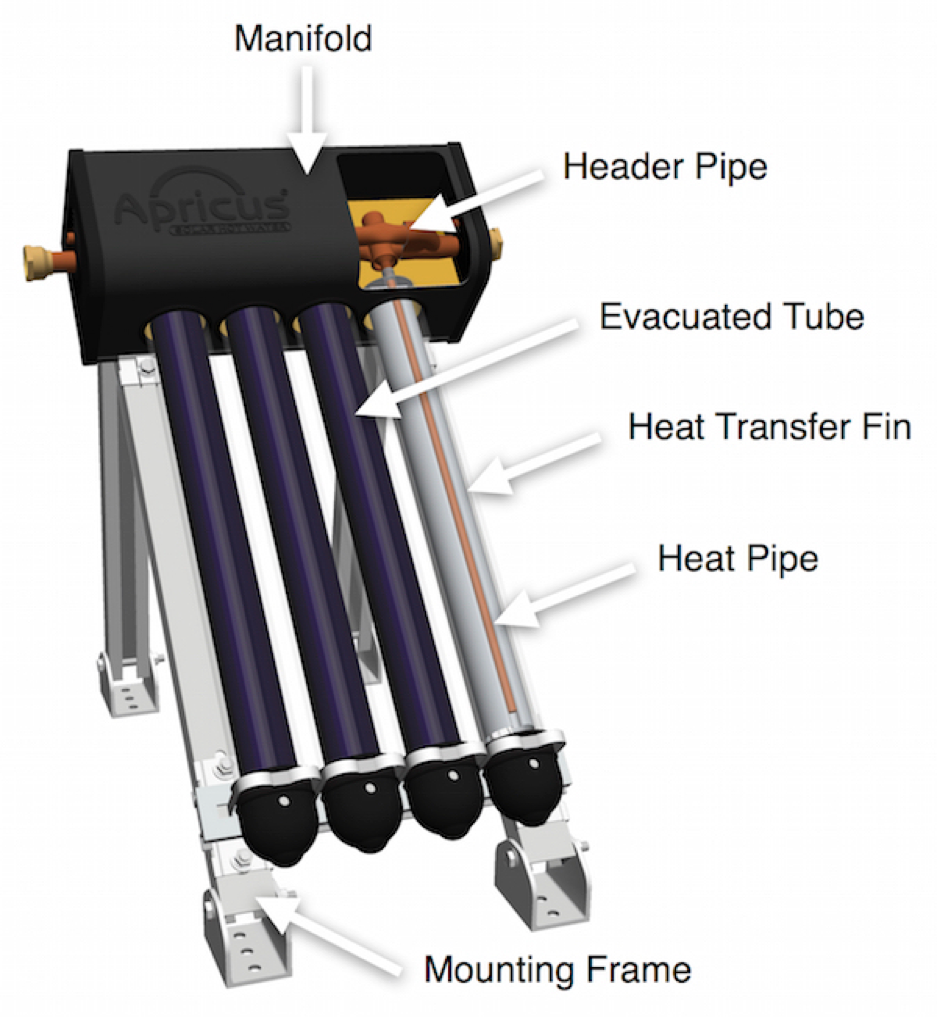

Evacuated Tube and Heat Pipe

The Apricus evacuated tube and heat pipe are assembled in a patented format that is different to any other product on the market. Rather than a centrally located heat pipe with heat transfer fins radiating out to the glass wall, the heat pipe is positioned directly against the glass wall, where the sun strikes. The aluminium heat transfer fin is tightly held against the top inner wall of the evacuated tube and heat pipe with a set of spring clips. This is an important design feature as over time, with exposure to high temperature, the Aluminium will soften. The spring clips gaurantee long term tight contact with the glass wall and heat pipe, which is essential for optimal performance.

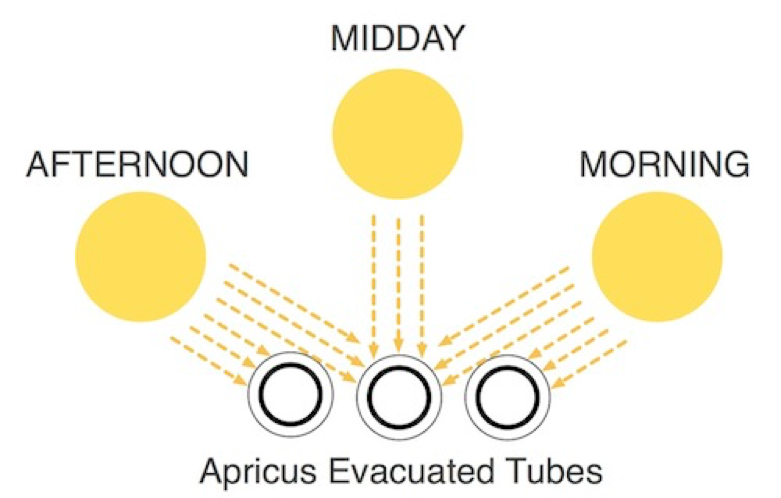

Passive Tracking

The round absorber surface of the evacuated tubes passively track the sun throughout the day, so no mechanical tracking device is required. This allows optimum surface area exposure from 7am to 5pm which covers the majority of the solar radiation each day. The Apricus evacuated tubes receive >20% more solar exposure compared to a flat absorber, allowing more solar energy conversion to heat each day.

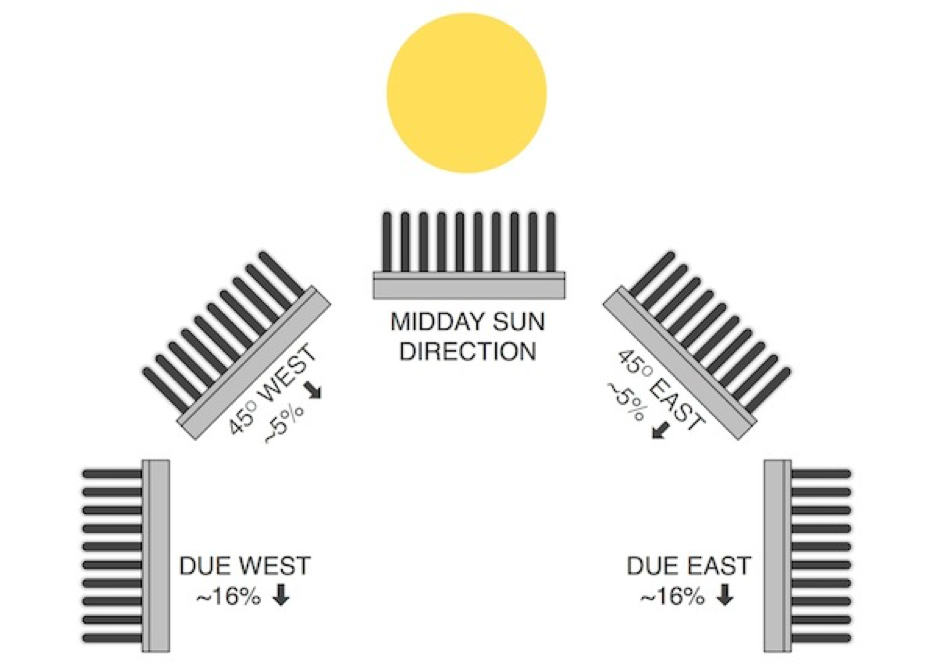

The passive tracking feature also allows the collector to be installed at directions East or West of equator pointing (North or South) without too much reduction in output. This provides a great degree of flexibility when selecting a suitable location for the collector on a building.

Header Design

The header pipe in the AP series evacuated tube solar collectors is designed for reliability. Large fluctuations in operating temperatures from day to night cause thermal expansion and contraction of the metal, which, combined with high operating pressures, places a huge amount of stress on brazed connection points.

In contrast to most other header designs that have 2 brazing points per heat pipe (60 for 30 tube collector), the Apricus design uses a twin contoured header pipe design that allows “dry” connection ports that don’t penetrate the header pipe. This means the header only has 4 brazing points in total. The result is an extremely reliable design that is able to withstand the rigors of daily thermal cycling.

Manifold Casing

The manifold casing is made of a strong but lightweight aluminium alloy that is folded to form a strong protective enclosure. The casing is finished with matte black PVDF coating that is UV stabilised for long term colour fastness.

Glass wool insulation is “baked like a cake” to form a complete structural shell around the header pipe. This design minimises the amount of metal used in the casing, reducing embodied CO2, and making it very lightweight. The lightness of the manifold box is a feature that installers value when carrying onto the roof. The largest manifold size, the ETC-30, is 2196 mm / 86.45″ long but only 9.2kg / 20.24 lbs.

Weatherability

Operating outside means that all the components of the collector must be able to withstand all that Mother Nature delivers, from freezing conditions, to the extreme heat and UV radiation of desert locations.

Apricus collectors are design with this is mind. A good example is the use of silicone rubber instead of plastics for the tube caps, rubber header seals and manifold covers. Silicone rubber is extremely durable, staying flexible in a wide temperature range. It is able to withstand over 200oC / 392oF and is extremely resistance to damage from UV light.

Design Improvements

The ETC design includes a range of incremental improvements over the previous AP model. These changes are based on internal R&D and customer feedback.

Evacuated Tubes: Improved absorption efficiency, coating durabilty and colour consistency. Average yearly collector output increase of around 5%.

Manifold Casing: More modern, rounded casing design together with higher quality PVDF finish for superior corrosion resistance and colour fastness.

Mounting Frame: Signifcantly stronger, high tensile anodized alumimium mounting frame and 316 (marine grade) stainless steel fasteners and hardware. Only two of new front tracks are required even in high wind load regions as they are stronger than 5 of the previous stainless steel design.